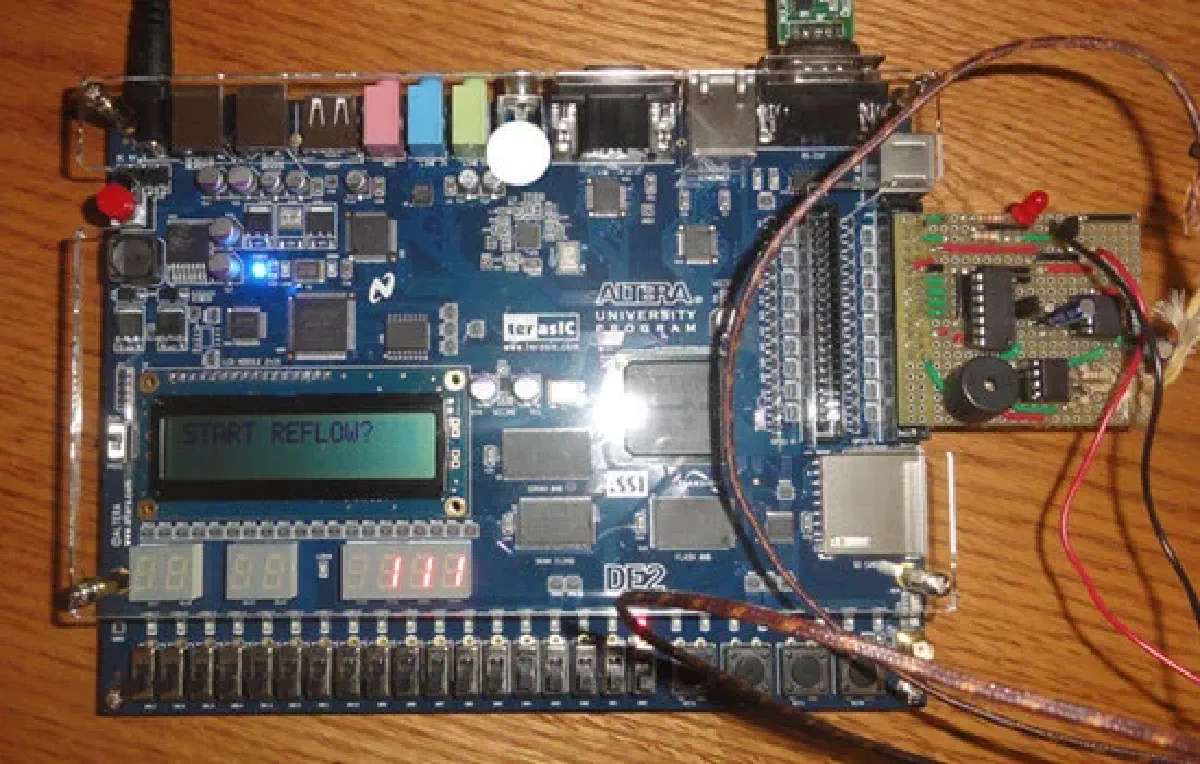

I collaborated with a team of six to engineer a precise reflow soldering oven controller using the DE2-8052 microcontroller (FPGA). The system aimed to adhere to industry-standard reflow thermal profiles.

Technical Architecture#

The project integrated low-level hardware control with high-level software interfaces:

- Firmware (Assembly): Wrote optimized assembly code to handle sensor data acquisition and heating element control loops.

- Middleware (Java): Developed a desktop application that communicated over serial (UART) to receive real-time temperature telemetry and visualize it on a live strip chart.

- Database (SQLite): Integrated a local database to store historical reflow profiles and run parameters.

- Interface (Android): Built a mobile app allowing users to remotely configure reflow parameters (preheat, soak, reflow, cooling) via the Java bridge.

Outcomes#

The solution successfully automated the soldering process, allowing users to monitor temperature curves in real-time on their mobile devices, significantly improving the user experience compared to traditional on-device 7-segment displays.